Making our own wood flooring

We pride ourselves in being able to supply our own products, manufactured to European standards with full quality control over the whole chain of production, from forest to floor. This is almost unique within the industry, as most retailers of wood flooring rely on purchasing materials from manufacturers from all over the world, without the knowledge and assurance that the product is ethically sourced or made to last.

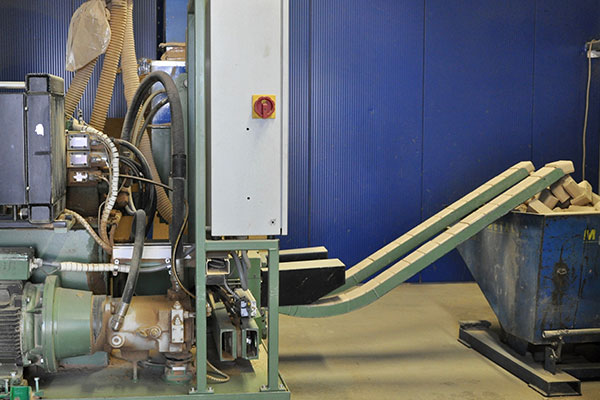

Have a look at how our Walnut Chevron Boards are made: